MAXIMUM WORKING WIDTH

The maximum working width is 139" (1000mm)

RATED VOLTAGE

The rated voltage is AC 380V/50Hz

MACHINE WEIGHT

The machine weighs 7055 lbs (3200 kg)

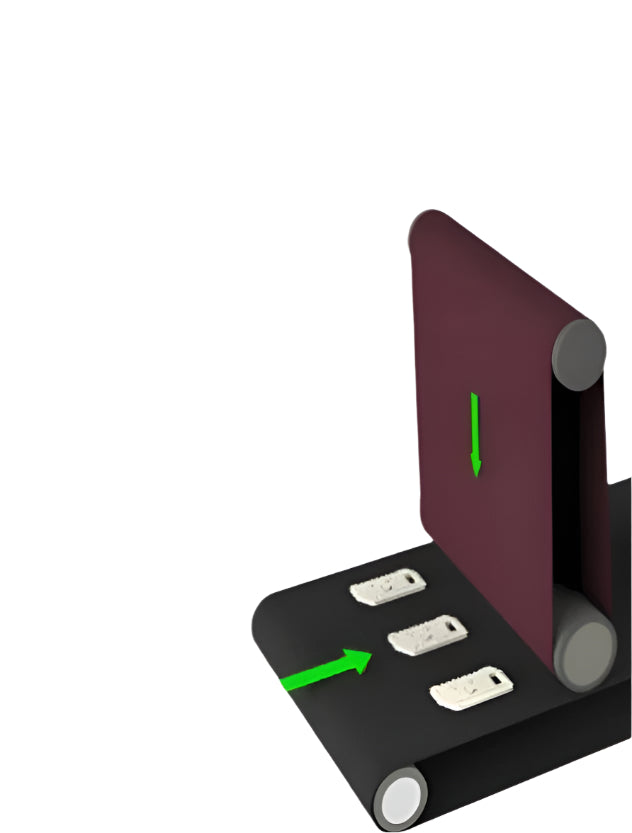

Professional equipment with three groups of grinding tools to polish surfaces and remove imperfections such as: Cutting slag, Stamping sharp edges, Burr of the inner/outer contour edge, Burr upside down corners.

Descarga la ficha técnica y folleto 1000TK AUTOMATIC SAND BELT DEBURRING MACHINE

| Abrasive material: | Alumina / Zirconium oxide / Ceramics |

| Abrasive producing area: | Germany/Japan/China |

| Abrasive specification (#): | 40 / 60 / 80 / 120 / 180 |

| Abrasive material: | Alumina / Zirconium oxide / Ceramics |

| Abrasive producing area: | Germany/Japan/China |

| Abrasive specification (#): | 80 / 120 / 180 / 240 / 400 |

The maximum working width is 139" (1000mm)

The rated voltage is AC 380V/50Hz

The machine weighs 7055 lbs (3200 kg)